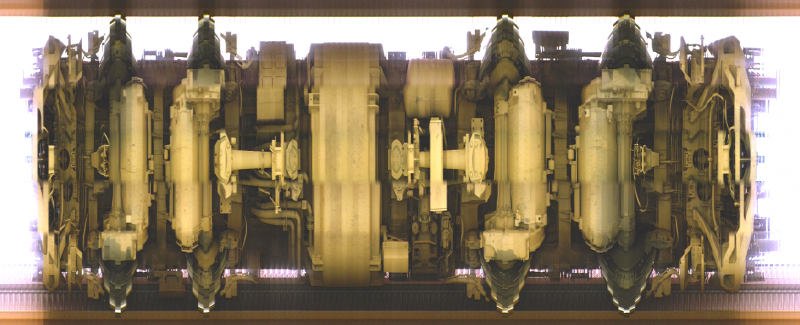

The VISOR-RnX range of advanced under vehicle inspection systems (UVIS) models is for inspecting trains – passenger and freight cars, locomotives and complete trains for maintenance and security purposes.

The general name for the VISOR Rail range is VISOR-RnX because we can provide VISOR Rail systems which have more than 5 cameras (“n”) and there are Portable and Static versions of the VISOR Rail range (X) .

If you need to inspect the whole exterior surface as well as the underside of a train, then we can provide a system with extra cameras. Because our technology uses multiple cameras and VisorSoft is flexible software, we can add more cameras and still display a composite image created from from all of them. Go to the Custom System page to see more information about special configurations.

- VISOR-RnP – for temporary installations

- VISOR-RnS – for Static, Surface installations

The VISOR Rail range models all use HD colour, angled cameras with wide angle lenses to ensure that you see from edge to edge and that you have a very high quality image. The “see around” capability provided by the angled cameras means that operators can see sideways into those difficult to see areas of the undercarriage.

Operational

VISOR-R5P and R5S models use the 5 camera VISOR Survey Unit (VSU) used in the Standard range. A rail adapter provides additional lighting, cable connection interfaces and fixing flanges.

VISOR-R5P and R5S models use the 5 camera VISOR Survey Unit (VSU) used in the Standard range. A rail adapter provides additional lighting, cable connection interfaces and fixing flanges.

The VSU for the VISOR-R5P or R5S models is installed between the rails and, as it sits above ground level, you do not need to excavate or provide drainage. Its height is lower than the head of the rail.

Mobility is a very important factor when deploying a UVIS for temporary activities. The VISOR-R5P can be deployed from the trunk of a car by 1 or 2 people in less than 5 minutes. It does not need a trailer to move it around.

VISOR-RnX models all use our proprietary VisorSoft image processing software to produce full colour composite images in less than 2 seconds from the image data from all of the cameras.

Sub-systems

All VISOR Rail range UVIS systems have two major subsystems:

VISOR Survey Unit (VSU) – the VSU is the camera sub-system which you normally install between the tracks but systems with more than 5 cameras may also have an external structure to support the additional cameras. So that you have the best possible view of the undercarriage, some of the cameras are angled so they see right out to the vehicle edges and into important areas like the brakes.

VISOR Control Unit (VCU) – the VCU is the system computer. It’s a high performance PC with an i7 Intel processor. It runs the VisorSoft software which acquires and processes the images from each of the cameras and generates and displays the composite and detail / zoom images on the LCD display. Every VISOR system is supplied with a high quality LCD display:

- 24″ desktop type for VISOR-RnS fixed systems;

- 19″ high brightness built-in display for the VISOR-RnP portable systems.

Key features

- Robustness – the VSU is tough. The VISOR-R5P and R5S models are welded aluminium structures with stainless steel subframes. Fixed systems also have structures to prevent damage to the VSU by hanging chains etc.

- Easy to use – the Operator interface is ergonomic and intuitive to operate whether by mouse or touchscreen, you will find it very easy to use VISOR.

- Excellent images – All VISOR UVIS systems display a complete underside image and all of the images displayed by a VISOR system are generated by HD colour GigE cameras. We use several cameras to ensure that you see the whole of the underside when you look at the image. And we keep all of the frames from each camera so that when you want to look at something in detail everything is still there in the stored file.

- Fast – The VCU uses a high performance Windows 7 Pro or 10 Pro based computer. VisorSoft is our custom image processing and management software and it’s also fast. So, in a few seconds after the train has passed over the VSU, you will see the image on the LCD display.

Click HERE to download the VISOR UVIS brochure.

All of the VISOR Rail range produce excellent images:

Features – VISOR-RnX range

VISOR Survey Unit:

- 5 or more colour digital GigE HD cameras

- 4 or more cameras angled to maximise “see around” capability

- Wide angle lenses to maximise fields of view of each camera

- Sees into difficult areas and around other items

- Sealed to better than IP67

- Uses small camera windows – minimising the probability of damage

- Robust – the VSU can be driven over by a truck without damage

VisorSoft software:

- It takes about 1 second to display the full composite underside image of a locomotive

- Better than 12x zoom without loss of resolution

- Frame by frame inspection facility

- Captures and displays front view of vehicle

- LPAssist provides you with a basic licence plate recognition capability

- Semi-automatic image comparison

- Record analysis and statistics facility

- Forward and reverse vehicle flow modes

VISOR Control Unit:

- i7 Intel processor running Windows 7 Pro or Windows 10 Pro.

- High capacity record storage

- LCD display – 24″ desktop for RnS and 19″ high brightness for the RnP model

- 19″ rack Control Unit

- large record storage capacity

- Interconnection cable – 20m for the RnS and 10m for the RnP model

- Optional 24vdc operation

- Optional volt free contacts to control peripheral equipment

The VISOR Rail range of advanced, high performance UVIS gives you excellent performance.